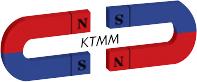

EMF Dry magnetic separators are great machines that provides an effective way to remove tramp iron from non magnetic material. These seppas are cool because they can separate magnetic stuff from a mix of other stuff. That’s how these dry electromagnetic separators work — nice!

They are efficient for dry material separation. They create a magnetic field with electricity, which attracts magnetic materials and separates them from nonmagnetic materials. This process is fast and also convenient for dividing iron and other iron based material from other materials.

Dry electromagnetic seaparators Another really great thing about strongest neodymium magnetss is that they don’t require water to operate. Their methods typically rely on water to process materials, but that can be messy and time-consuming. Dry electromagnetic separators do this quite well as the process is clean and fast and is an excellent way of sorting materials.

Dry electromagnetic separators are great at sorting magnetic material, not so good at accurately sorting conductive materials. The magnetic field they generate is strong — and highly controlled — which means they are good at sorting out only magnetized materials, and everything else keeps going. This accuracy is critical in industries that require specific materials to be sorted out.

Companies can minimize waste by separating materials using a dry electromagnetic separator, to ensure that they are only separating the materials they require. This allows them to be efficient and not waste items they could use, which saves them money and resources. It’s also smart ecologically and economically.

A dry type electromagnetic separator can be more convenient in the benefiting of dry material. Less of the catalyst is needed and the splitting of materials can happen extremely quickly, potentially saving companies time and money. No need to sacrifice volume in the name of efficiency.

As a national high-tech enterprise with an annual capacity of 10,000 tons, we specialize in a comprehensive range of permanent magnets, including NdFeB, Ferrite, SmCo, AlNiCo, and Flexible Magnets, meeting diverse industrial needs from wind turbines to consumer electronics.

Through strategic cooperation with leading raw material suppliers like Northern Rare Earth and backed by 15 years of magnet manufacturing expertise, we offer stable material sourcing and flexible OEM/ODM services tailored to specific customer designs and applications.

Equipped with a state-of-the-art testing laboratory and adhering to ISO9001 and RoHS standards, we implement strict quality controls throughout production, ensuring high corrosion resistance, fine finishing, and consistent performance across all magnet grades.

With magnets exported worldwide and used in high-demand sectors such as automotive, medical (MRI), and renewable energy, our experienced R&D team focuses on customer-driven solutions, delivering reliable, cost-effective magnets with strong technical support and application expertise.

Copyright © Ningbo Ketai Magnetic Material Co., Ltd. All Rights Reserved