Pot magnets are a largely unnoticed part of automotive assembly, however they do the heavy lifting (so to speak!) when it comes to making things quicker and stronger. These magnets are kinda like superheroes in that they do a bit of a better job holding the cars together quicker, stronger. Learn About How Pot Magnets Can Increase Efficiency and Reliability in Automotive Manufacturing.

Pot Magnets in Automotive Assembly

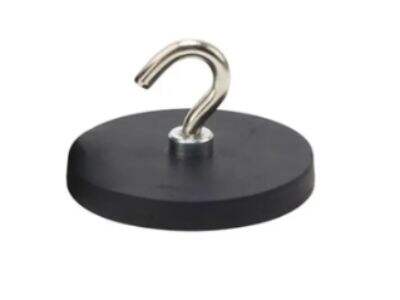

Pot magnets are just metal discs, the magnet is located inside in a standard shape of noodles These are situated intermittently down the creation line to help metal parts. This ensures that workers are able to easily snap parts together without worrying about them moving. Pot magnets are also used to keep things straight, such as the cars, do not fall apart when built.

What Is the Role of Pot Magnet in Automobile Manufacturing Process?

Pot magnets: Ketaimag increases speed on the automotive assembly line with pot magnets. This pot magnet eliminates the need for workers to continually reposition parts that are always moving around, thereby speeding up the work. Thus, enabling the production of additional vehicles at a faster pace. It acts like a secret weapon that helps the team to complete things at warp speed.

Advantages Of Using Pot Magnets in Automotive assembly lines

There are many advantages that pot magnets provide in Ketaimag development of automotive assembly lines. This is because the neodymium pot magnet are actually very tough ones so they can firmly hold heavy parts at ease. This assists with preventing errors and makes sure each car is made to final. Pot magnets are not only strong in strength, they are also built to last so you can use them again and again without any decline in their performance. This eventually saves time and money.

Pot Magnets in Automotive Assembly

Pot magnets are in wide use in the automotive industry for its efficiency and durability. They can be mounted on conveyor belts to prevent the parts from slipping off. The pot shaped magnet have also found their place on robot arms helping them to effortlessly grab and then move metal pieces. In the end, these little magnets make sure every car built at Ketaimag represents quality and safety.

How Can Pot Magnets Help Automotive Engineering?

There is no doubt as to the influence of pot magnets in automotive manufacturing. In addition to streamlining the fabrication process, they assist in achieving a durable solution as well as strength and stiffness to the vehicles constructed. Ketaimag has now got round this issue and because of their use of pot magnets, they are able to make cars that are safer, more reliable AND built for longevity. It may be small but it is very important for the world of automotive assembly.

Pot magnets are required handiest in vehicle Meeting and beautify performance, reliability. These powerful magnets not only simplify the manufacturing of cars at Ketaimag, but also ensures that every car built meets these high standards. The use of pot magnets allows our team to work quicker, smarter, and more accurately. It is astonishing that these little magnets ship, and by the billions — just for the automotive applications!